Silane Adhesion Promoters

Silane Adhesion Promoters

Silanes are compounds whose molecules (based on the silicon element) contain organo-functional groups. This combination of organic and inorganic elements allows silanes to form chemical bonds between dissimilar surfaces. Silica (or silicon dioxide) is an extremely stable compound and comprises some of the most abundant, weather-resistant materials on earth. Through the hydrolysis and condensation of organo-functional silanes, you can achieve a silica-like product that really sticks!

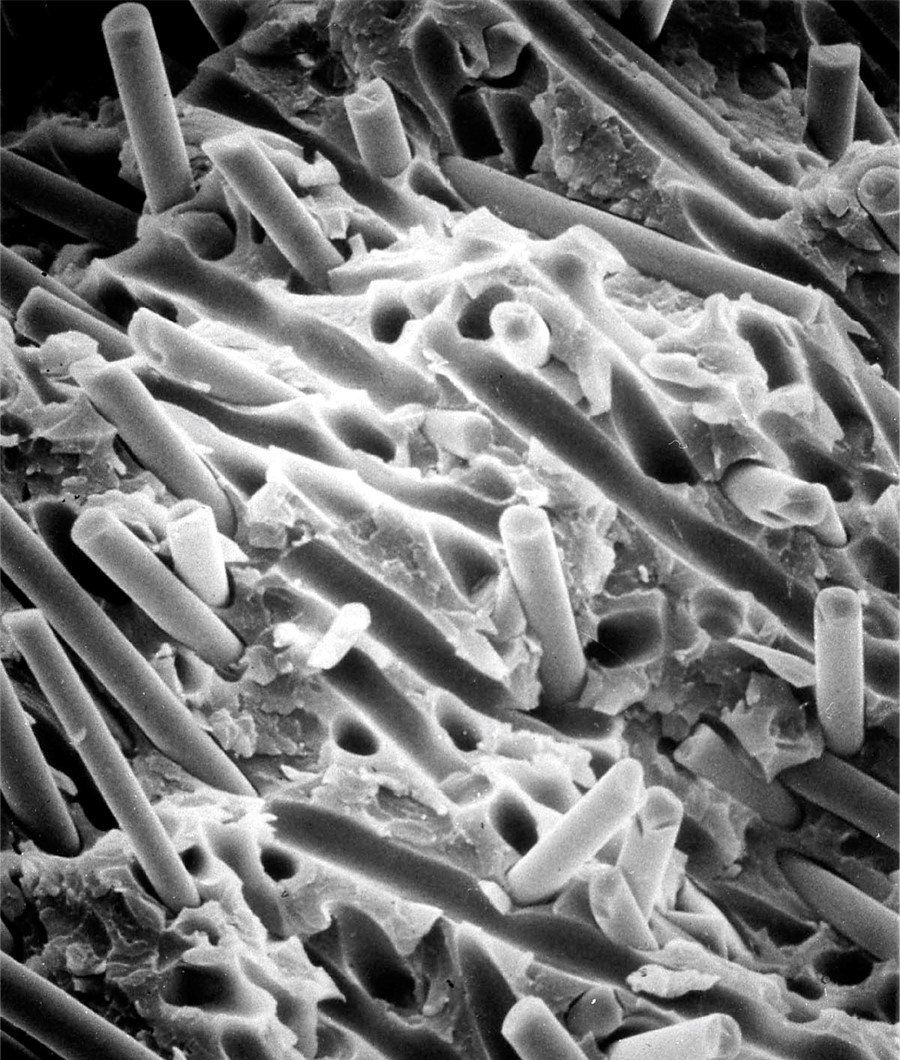

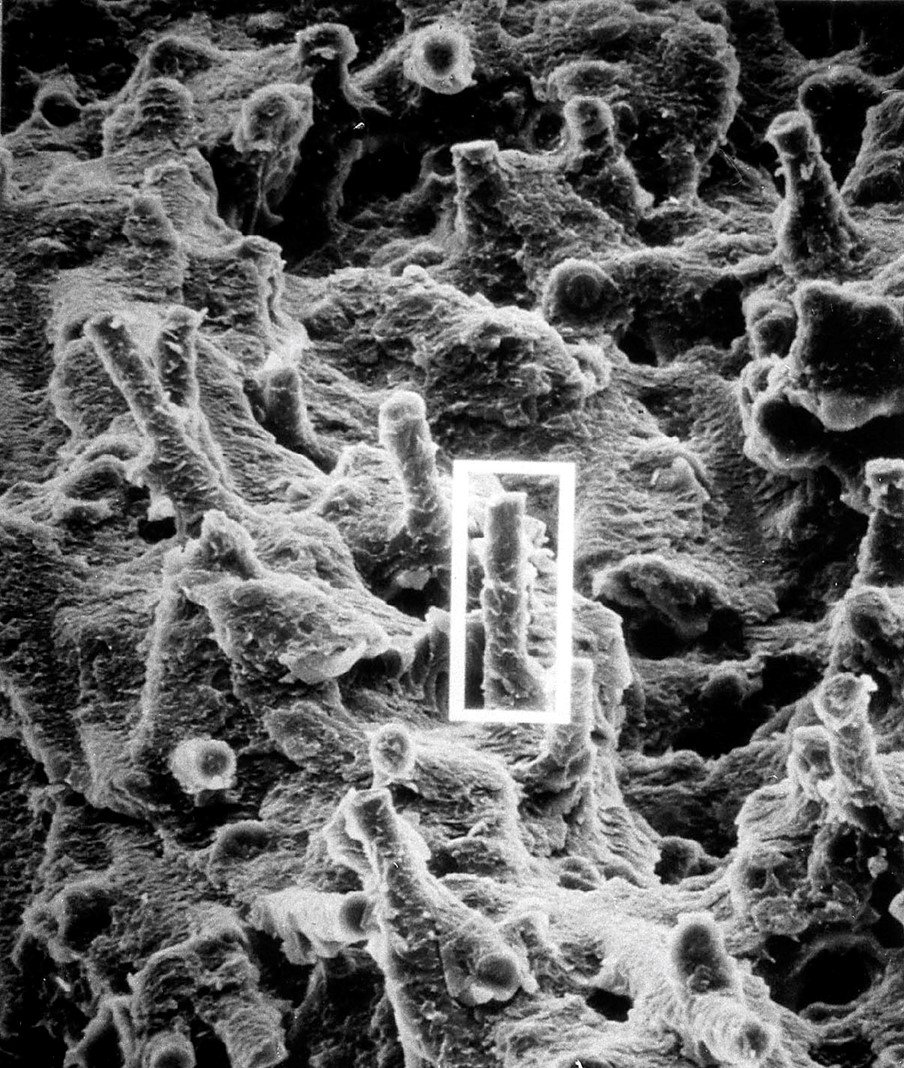

The Scanning Electron Microscope (SEM) images below provide a small glimpse into an application for organofunctional silanes. These images show the effect of a silane on glass fiber in a reinforced thermoplastic composite.

When alkoxysilanes are reacted with water (hydrolysis) they form chemical bonds through the silicon-oxygen groups to inorganic surfaces (condensation). They are most often used in mineral or glass fiber coating (as the pictures show), or to help with dispersion of pigments, or as “adhesion promoters” on surfaces. Organic reactive groups on the other end of the molecule can include primary Amine, Epoxide, Methacrylate, Mercaptan (including low odour), Vinyl, etc.

Silanes Available

Silsource Inc. supplies silanes in a range of reactive chemistries and with two main hydrolysable groups: Methoxy and Ethoxy. These groups determine the speed of the hydrolysis reactions, they can be chosen for HS&E reasons, or in some formulations, the ethanol liberated from hydrolysis can have a positive effect on coating quality. In general, ethoxy silanes will hydrolyze at a slower rate than their methoxy equivalents; however, the rate of hydrolysis can and should be controlled using acidic (preferred) or alkaline catalysts. With a variety of organic-reactive groups available, and different hydrolysable groups on the silicon, silanes are highly versatile products which can be used in a wide range formulations and manufacturing processes.

Some of our most popular silanes include:

- 3-Aminopropyltriethoxysilane (APTES)

- N-2-(Aminoethyl)-3-aminopropyltrimethoxysilane

- 3-Glycidoxypropylmethyldiethoxysilane

- 3-Glycidoxypropyltrimethoxysilane

- 3-Methacryloxypropyltrimethoxysilane

- Vinyltrimethoxysilane (VTMO)

Choosing the Right Silane

Silanes are resilient products which help form permanent chemical bonds; improving the heat resistance, weatherability, strength, hydrophobicity and other properties of various materials. The Organo-Functional part of silanes can be changed to suit a broad range of applications, depending on the polymer chosen. Choosing the right silane for your application can be challenging, but by using the guide below and contacting our experts, we can work towards a solution! The organic functional groups listed below can be used with Thermoplastic resins, Thermosetting resins, or Elastomeric applications:

Acryloxy - Polyethylene, Polypropylene, ABS, Unsaturated Polyester, Sulfur or peroxide-crosslinked EPDM

Amino - Acrylic, Epoxies, Furan, Melamine, Nitrile Rubber, Nylon, Phenolics, Polystyrene, PVC, Urethanes

Isocyanate - Melamine, PBT, PET, Urethane

Mercapto - Sulfur-crosslinked EPDM, SBR, Nitrile, Neoprene, Polysulfide, Urethane rubber

Ureide - Nylon, Phenolics – Urethane

Vinyl - Polyethylene, Polypropylene, Unsaturated polyester, Sulfur or Peroxide-crosslinked EPDM

Functional groups must be evaluated by customers for compatibility with listed resins. Additional reactive chemistries may be available upon request. This should be used as a guide only. Please contact Silsource

for more info.

VOC Free Coupling Agents

In addition to the traditional alkoxysilanes, we also have a selection of low VOC or VOC Free silane coupling agents. Without alkoxysilyl groups, these products are simply organofunctional silanols, which means the amount of methanol or ethanol (which results from hydrolyzation) is reduced by 99% or more. Also, by eliminating the hydrolysis step, these silanes ready to use right away, they are non-flammable, release virtually no alcohol, and are much more environmentally friendly.

Two popular VOC free options are:

- Aminosilane oligomer in aqueous solution - Same performance as 3-Aminopropyltriethoxysilane (APTES) is expected, comes ready to use, non-flammable

- Alkylene Glycol siloxane (aqueous) - Active ingredients 30wt% with a pH

of 2-4, mixture of glycol functional siloxanes in water.

Applications can include uses as primers, binder additives, water-based paint additives, or surface treatments. Contact Silsource for more information and to inquire about availability.

Long-Chain Spacer Silane Coupling Agents

To meet the ever-changing needs of our society, new silanes have been developed to provide even higher performance. These products can improve the dispersibility of fillers, reduce formulation viscosity, increase hydrophobicity, greatly increase reactivity, and improve adhesion. They are best suited for specialty applications (Aerospace, Dental, etc.) where typical silanes do not meet performance requirements.

Examples of these long (carbon) chain silanes are:

- Amine functional: N-2-(Aminoethyl)-8-aminooctyltrimethoxysilane

- Epoxy functional: 8-Glycidoxyoctyltrimethoxysilane

- Methacrylic functional: 8-Methacryloxyoctyltrimethoxysilane

Contact Silsource

for more information about these products.

Find your application below, or explore other applications for silanes:

- Cross-linking Polyethylene - Tubing-PEX B, electrical wire coverings

- Copolymerization of Silane Monomers for Acrylic Resins and Paints

- Amino Functional Alkoxysilane - Modified Urethanes

- Elastomeric Polyolefin Based Compounds

- Mineral filled phenolics, epoxies, polyamides, PBT

- Other glass fiber reinforced thermoset and thermoplastics

- Improves dispersion and adhesion between magnetic powders and resins resulting in higher magnetic orientation and mechanical strength

- Insulation - glass fiber and mineral wool to improve strength and moisture resistance

- Anti-corrosion coatings for metals

- Additive for hot-melt adhesives for improved adhesion

- Synthetic quartz countertops

- Hydrophobic coatings of glass, silica, or alumina

- And More!

Click to contact Silsource today

to discuss your application and take advantage of the benefits silanes can offer to your formulation!